Product Description

Product Description

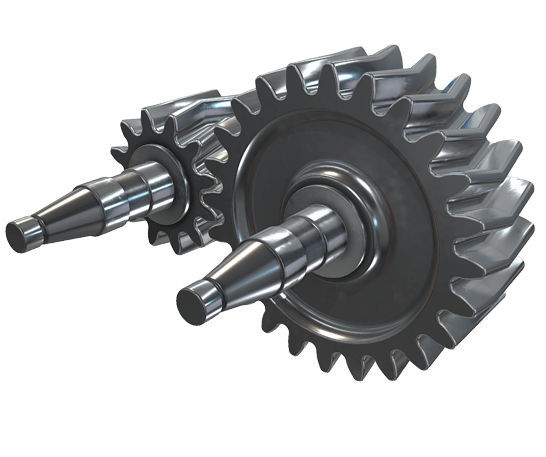

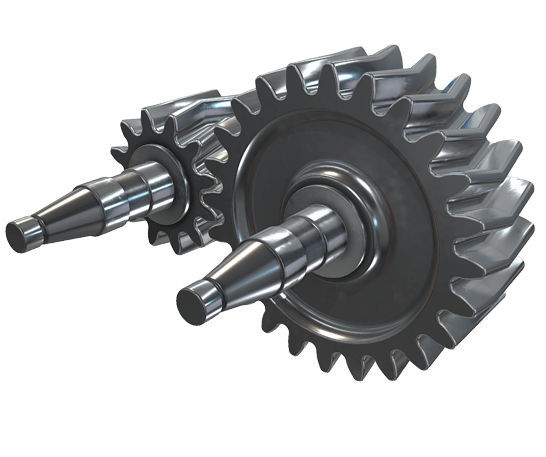

Herringbone gears are a specific type of gear that feature a unique double helix shape resembling the bones of a fish, hence the name “herringbone.” They are characterized by their distinctive V-shaped teeth that are arranged in a herringbone pattern.

Features

Double Helix Shape: The most distinctive characteristic of herringbone gears is their double helix shape, which allows for smoother and more efficient operation compared to traditional spur gears.

Self-Aligning: Due to the opposing helix angles on either side of the gear, herringbone gears are self-aligning. This helps to reduce axial thrust and prevents gear misalignment.

High Load Capacity: Herringbone gears are capable of handling high loads and transmitting significant amounts of power due to their robust design.

Reduced Vibration and Noise: The double helix design helps to cancel out axial forces and minimize vibration and noise during operation, making them ideal for applications where noise reduction is important.

Functions

Power Transmission: Like other types of gears, herringbone gears are primarily used to transmit power between parallel shafts while maintaining a constant speed ratio.

Direction Change: Herringbone gears can change the direction of rotation between 2 shafts while transmitting power efficiently.

Speed Reduction or Increase: By using herringbone gears with different numbers of teeth on the mating gears, speed reduction or increase can be achieved.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Double Helical Gear |

| Material: | Alloy Steel |

| Transport Package: | Wooden Case |

| Customization: |

Available

| Customized Request |

|---|

How do you choose the right size herringbone gear for your application?

Choosing the right size herringbone gear for your application involves considering several factors and performing engineering calculations. Here’s a detailed explanation of the steps involved in selecting the appropriate size herringbone gear:

- Determine the Application Requirements: Start by understanding the specific requirements of your application. Consider factors such as the input and output speeds, torque loads, power requirements, duty cycle, and operating conditions. Determine the desired service life, efficiency, and reliability expectations for the gear system.

- Calculate the Gear Ratios: Determine the required gear ratios based on the speed and torque requirements of your application. Gear ratios define the relationship between the rotational speeds and torques of the input and output shafts. Select appropriate gear ratios that fulfill the desired performance objectives.

- Calculate the Load and Torque: Estimate the maximum load and torque that the herringbone gear will experience during operation. Consider both static and dynamic loads, shock loads, and any potential overload conditions. Calculate the required torque capacity of the gear system based on these load considerations.

- Consider the Size and Space Constraints: Evaluate the available space and size constraints in your application. Measure the available distance for gear installation, including the gear’s diameter, width, and axial length. Consider any restrictions on the gear’s physical dimensions and ensure that the selected gear size fits within the available space.

- Determine the Gear Module: The gear module is a parameter that defines the size and number of gear teeth. Calculate the gear module based on the desired gear ratios, torque capacity, and available space. The gear module is typically determined by considering a balance between gear tooth strength, contact ratio, and manufacturing feasibility.

- Perform Gear Design Calculations: Utilize standard gear design formulas and calculations to determine the required number of gear teeth, pitch diameter, helix angles, and other gear dimensions. Consider factors such as gear tooth strength, contact ratio, tooth profile optimization, and gear manufacturing standards. These calculations ensure that the selected gear size can handle the anticipated loads and provide reliable performance.

- Consult Manufacturers and Standards: Consult gear manufacturers, industry standards, and guidelines to ensure compliance with best practices and safety requirements. Manufacturers can provide technical expertise, recommend suitable gear sizes, and offer guidance on material selection, heat treatment processes, and gear quality standards.

- Consider Cost and Availability: Evaluate the cost implications and availability of the selected gear size. Consider factors such as material costs, manufacturing complexity, lead times, and the overall economic feasibility of the gear system. Balance the desired performance with cost considerations to arrive at an optimal gear size.

It’s important to note that selecting the right size herringbone gear requires expertise in gear design and engineering. If you lack the necessary knowledge, it is advisable to consult with experienced gear engineers or manufacturers who can assist in the selection process.

In summary, choosing the right size herringbone gear involves determining the application requirements, calculating gear ratios and torque loads, considering size constraints, determining the gear module, performing gear design calculations, consulting manufacturers and standards, and considering cost and availability. Following these steps ensures that the selected herringbone gear size meets the specific needs of your application and provides reliable and efficient operation.

Are herringbone gears suitable for high-torque applications?

Herringbone gears are well-suited for high-torque applications due to their design characteristics and advantages. Here’s a detailed explanation of why herringbone gears are suitable for high-torque applications:

- Large Surface Area of Contact: Herringbone gears have a larger surface area of contact between the gear teeth compared to conventional spur gears. This increased contact area allows herringbone gears to distribute the torque load more effectively. The larger contact area helps prevent tooth deflection and distributes the load across a greater number of teeth, resulting in improved torque transmission capabilities.

- Higher Torque Capacity: The design of herringbone gears enables them to handle higher torque loads. The opposing helix angles of the teeth in herringbone gears cancel out the axial thrust, which is generated during gear meshing. This cancellation of axial thrust allows herringbone gears to transmit higher torque without the need for additional thrust bearings or mechanisms. The increased torque capacity of herringbone gears makes them suitable for demanding applications that require high torque transfer.

- Reduced Gear Tooth Deflection: Herringbone gears exhibit reduced tooth deflection compared to spur gears. The double helical arrangement of the teeth in herringbone gears helps counteract the bending forces that can cause tooth deflection. This characteristic allows herringbone gears to maintain a more precise gear mesh, even under high torque loads. The reduced tooth deflection enhances the overall performance and reliability of herringbone gears in high-torque applications.

- Compact Gearbox Design: The high torque capacity of herringbone gears enables the design of more compact gearboxes. The ability to transmit higher torque loads in a smaller package can be advantageous in applications where space is limited. The compact design not only saves space but also reduces the overall weight of the system, making herringbone gears suitable for high-torque applications with size and weight constraints.

- Smooth Operation: Herringbone gears provide smooth and precise gear engagement, even under high-torque conditions. The opposing helix angles of the teeth facilitate gradual meshing and unmeshing, reducing impact and shock loads. The smooth operation minimizes vibrations and noise, which is particularly important in high-torque applications where excessive vibrations can lead to premature wear or component failure.

While herringbone gears offer several advantages for high-torque applications, it’s important to consider other factors such as lubrication, gear material, and system design. Proper lubrication and the use of high-strength materials can further enhance the performance and durability of herringbone gears in high-torque applications. Additionally, system design considerations, such as proper alignment, stiffness, and maintenance practices, should be taken into account to ensure optimal performance and longevity of herringbone gears in high-torque scenarios.

What is a herringbone gear and how does it work?

A herringbone gear, also known as a double helical gear, is a specialized type of gear with a unique tooth design. Here’s a detailed explanation of what a herringbone gear is and how it works:

A herringbone gear consists of two helical gear sections that are mirror images of each other and are joined together to form a V-shaped or herringbone-shaped tooth profile. Unlike conventional helical gears, which have a single helix angle and a continuous spiral tooth profile, herringbone gears have two opposing helix angles, resulting in a “V” shape when viewed from the end.

The primary advantage of the herringbone gear design is its ability to eliminate axial thrust or end thrust forces that are generated in helical gears. In a conventional helical gear, the helix angle of the teeth causes an axial force along the gear’s axis during rotation. This axial force can create significant thrust loads that need to be counteracted using thrust bearings or other mechanisms.

By using the double helix design of herringbone gears, the opposing helix angles cancel out the axial forces generated by each helical section. This cancellation of axial forces eliminates the need for thrust bearings and allows herringbone gears to transmit torque smoothly without axial movement or thrust loads.

When a herringbone gear is in operation, the angled teeth of the two helical sections engage with each other, similar to how helical gears mesh. The contact between the teeth occurs gradually, starting from one end of the gear and progressing towards the other end. The overlapping or interlocking tooth profiles ensure a continuous and smooth transfer of power.

The herringbone gear design offers several advantages:

- Axial Load Balancing: The opposing helix angles in herringbone gears balance out the axial forces, eliminating the need for thrust bearings and reducing wear on the gear teeth.

- Increased Load Capacity: The V-shaped tooth profile of herringbone gears provides increased tooth contact area compared to a single helix gear. This leads to improved load distribution and higher load-carrying capacity.

- Reduced Vibration and Noise: The double helix design of herringbone gears helps cancel out vibrations and reduce noise during operation. The opposing helix angles minimize tooth deflection and ensure smoother engagement between the gear teeth.

- Bidirectional Power Transmission: Herringbone gears can transmit power in both directions due to their symmetrical tooth profiles. This makes them suitable for applications where reversing or bidirectional power transmission is required.

- High Efficiency: The continuous and gradual engagement of the herringbone gear teeth results in improved efficiency by reducing sliding friction and minimizing backlash.

Herringbone gears are commonly used in various industrial applications, including power transmission systems, heavy machinery, oil and gas equipment, marine propulsion systems, and high-speed gearboxes. Their unique design and benefits make them well-suited for applications that require high torque transmission, smooth operation, and minimal axial thrust.

editor by Dream 2024-04-22