Product Description

Product Description

|

|

|||||||||||||||||||||||

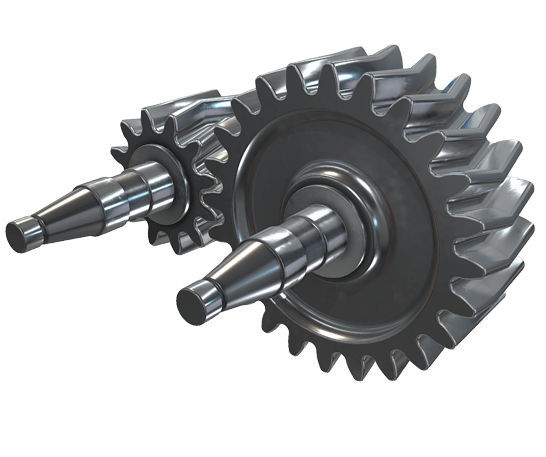

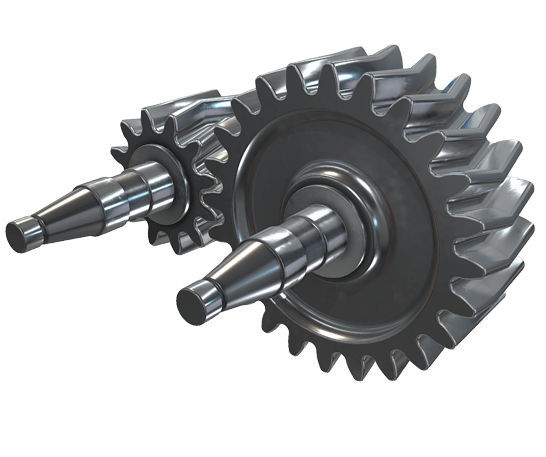

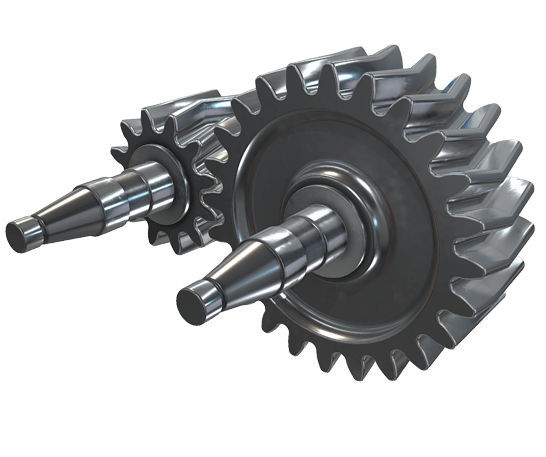

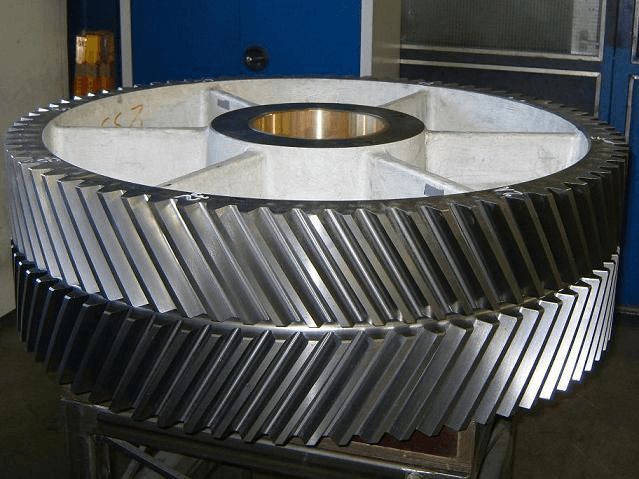

★★★High Load Capacity: Large helical gear shafts are designed to handle significant loads and transmit high levels of torque. The helical gear design allows for a greater tooth engagement, resulting in improved load distribution and higher load-carrying capacity compared to other gear types.

★★★Smooth and Quiet Operation: Helical gears have a gradual engagement of teeth, which reduces noise and vibration during operation. The helix angle of the teeth helps to distribute the load smoothly, minimizing impact and ensuring a quieter gear system.

★★★Increased Efficiency: The helical gear design provides a larger contact area between the teeth, resulting in higher efficiency compared to other gear types. This leads to reduced power losses and improved overall system efficiency.

★★★Greater Tooth Strength: The helical gear teeth are longer and have a larger surface area compared to spur gears, providing increased tooth strength. This makes large helical gear shafts more resistant to wear and fatigue, allowing them to withstand heavy loads and prolonged use.

★★★Improved Gear Meshing: Helical gears offer a gradual engagement of teeth, which results in a smoother meshing action. This helps to minimize backlash, improve gear accuracy, and reduce the likelihood of tooth damage during gear engagement.

★★★Versatility: Large helical gear shafts can be used in a wide range of applications, including industrial machinery, heavy equipment, marine propulsion systems, and power transmission systems. Their versatility makes them suitable for various industries and sectors.

★★★Reliability and Durability: The use of high-quality materials, precise manufacturing techniques, and rigorous quality control ensures that large helical gear shafts are reliable and durable. They are designed to withstand heavy loads, extreme operating conditions, and long service life.

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Customization: |

Available

| Customized Request |

|---|

How do herringbone gears contribute to smooth power transmission?

Herringbone gears contribute to smooth power transmission through their unique design and characteristics. Here’s a detailed explanation of how herringbone gears achieve smooth power transmission:

- Opposing Helix Angles: Herringbone gears have a double helical tooth profile with opposing helix angles on each side. The helix angles are inclined in opposite directions to each other. This design feature helps to cancel out axial and radial forces that would occur in single helical gears. The opposing helix angles create a self-centering effect that promotes proper tooth engagement and load distribution, reducing gear vibrations and ensuring smooth power transmission.

- Reduced Vibration and Noise: The opposing helix angles of the herringbone gear teeth minimize gear vibrations during operation. When the teeth of one side of the gear mesh with the teeth of the other side, the opposing helix angles create a balanced force distribution that counteracts any tendency for the gear to move laterally. This results in reduced vibration and noise levels, making herringbone gears ideal for applications where quiet operation is desired, such as precision machinery and automotive transmissions.

- Large Contact Area: Herringbone gears have a larger contact area compared to spur gears. The double helical tooth profile allows for overlapping engagement of the gear teeth, resulting in a larger contact ratio. This increased contact area distributes the transmitted torque over more teeth, reducing the stress on individual teeth and promoting smoother power transmission. The larger contact area also helps to minimize wear and improve the overall durability of the gear system.

- Enhanced Load Distribution: The double helical tooth design of herringbone gears provides improved load distribution along the tooth surfaces. The opposing helix angles help to evenly distribute the transmitted load between the two sides of the gear. This balanced load distribution minimizes localized stress concentrations and reduces the risk of tooth failure. It ensures that the torque is transmitted smoothly across the entire tooth profile, resulting in efficient power transmission and reduced wear.

- Efficient Torque Transfer: Herringbone gears offer efficient torque transfer due to their large contact area and overlapping tooth engagement. The double helical tooth profile provides a larger contact ratio compared to spur gears, allowing for a greater number of teeth in contact at any given time. This increased contact ratio distributes the torque more evenly, reducing the risk of tooth shear and improving power transmission efficiency. The efficient torque transfer contributes to smooth and reliable operation of the gear system.

These factors combined – opposing helix angles, reduced vibration and noise, large contact area, enhanced load distribution, and efficient torque transfer – contribute to the smooth power transmission capabilities of herringbone gears. Their design minimizes the effects of axial and radial forces, promotes balanced load distribution, and ensures reliable and efficient power transfer in various applications.

Can you provide examples of machinery that use herringbone gears?

Herringbone gears are widely used in various machinery and mechanical systems that require high torque transmission, smooth operation, and reduced noise levels. Here are some examples of machinery and applications where herringbone gears are commonly employed:

- Marine Propulsion Systems: Herringbone gears are commonly found in marine propulsion systems, including ship engines and marine gearboxes. They are used to transmit power from the engine to the propeller shaft, providing efficient torque transfer and smooth operation in marine vessels.

- Mining Equipment: Herringbone gears are used in heavy-duty mining equipment, such as crushers, conveyors, and excavators. These gears can handle high loads and provide reliable power transmission in demanding mining operations.

- Turbines and Power Generation: Herringbone gears are utilized in various power generation applications, including steam turbines and hydroelectric generators. They help transmit torque from the turbine or generator shaft to other components, such as the gearbox or electrical generator, ensuring efficient power generation.

- Rotating Kilns and Dryers: Herringbone gears are commonly employed in rotating kilns and dryers used in industries such as cement manufacturing and chemical processing. These gears facilitate the rotation of the kiln or dryer, ensuring proper heat distribution and material processing.

- Metal Rolling Mills: Herringbone gears are utilized in metal rolling mills to transmit power from the motor to the rollers. They enable precise and synchronized movement of the rolls, allowing for the shaping and forming of metal sheets or bars in the rolling process.

- Paper and Pulp Industry: Herringbone gears are used in machinery and equipment involved in the paper and pulp industry, such as paper machines, pulpers, and digesters. These gears facilitate the movement of various components, including rollers and conveyors, ensuring smooth and efficient paper production processes.

- Textile Machinery: Herringbone gears find applications in textile machinery, including spinning machines, weaving looms, and knitting machines. They assist in the movement and synchronization of various components, such as spindles, shuttles, and fabric feeders, enabling precise and efficient textile production.

- Machine Tools: Herringbone gears are utilized in machine tools, such as gear hobbing machines, milling machines, and lathes. These gears help transmit power from the motor to the tooling components, allowing for precise and controlled machining operations.

These examples represent just a few of the many applications where herringbone gears are employed. Herringbone gears are valued for their ability to handle high loads, provide smooth operation, and reduce noise levels, making them suitable for a wide range of machinery and mechanical systems.

How do herringbone gears differ from other types of gears?

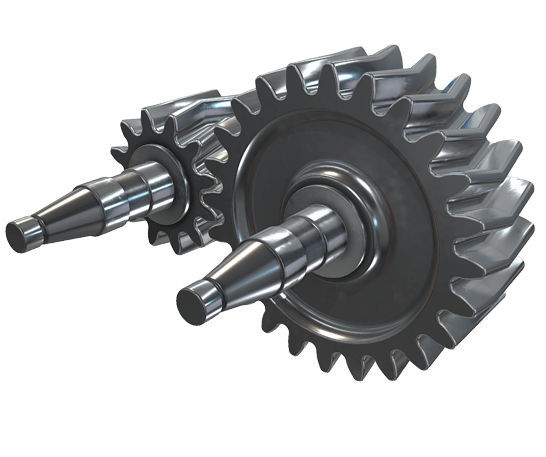

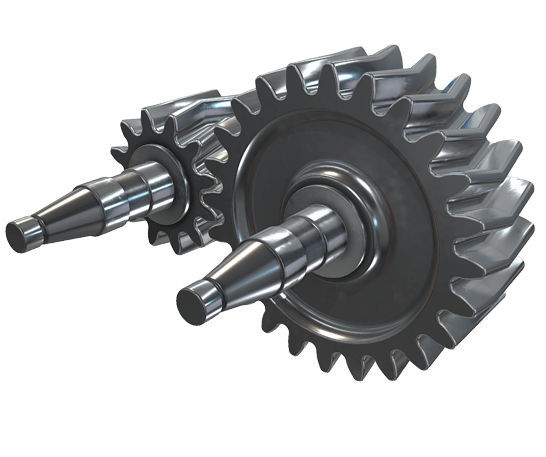

Herringbone gears, also known as double helical gears, possess distinct characteristics that set them apart from other types of gears. Here’s a detailed explanation of how herringbone gears differ from other gears:

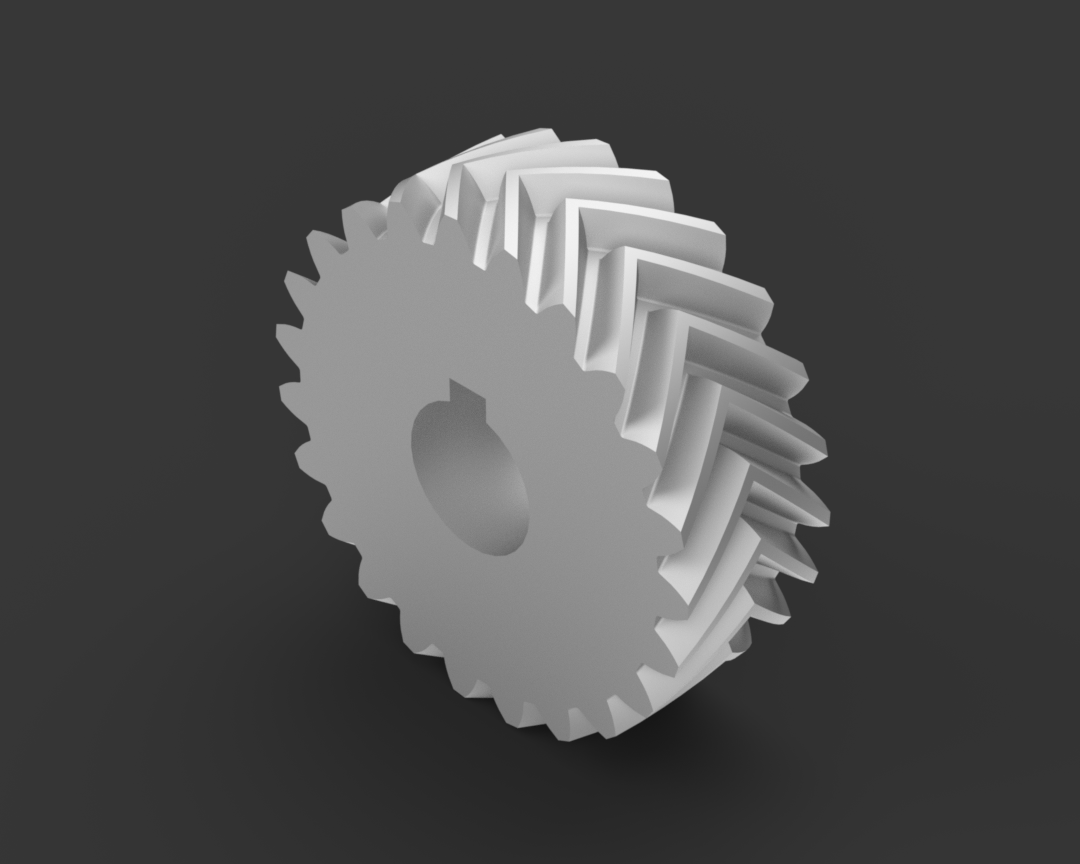

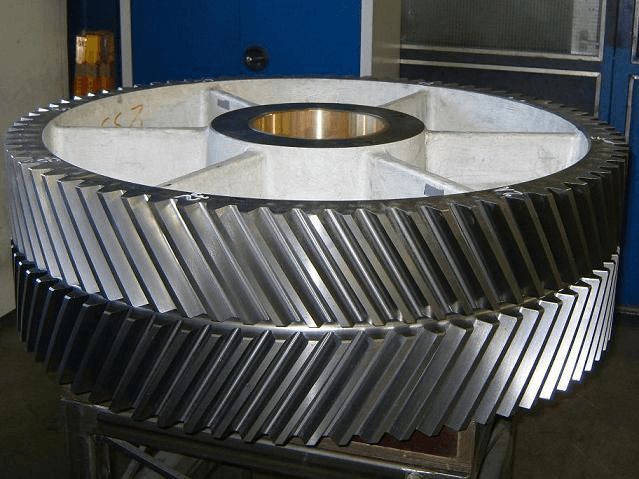

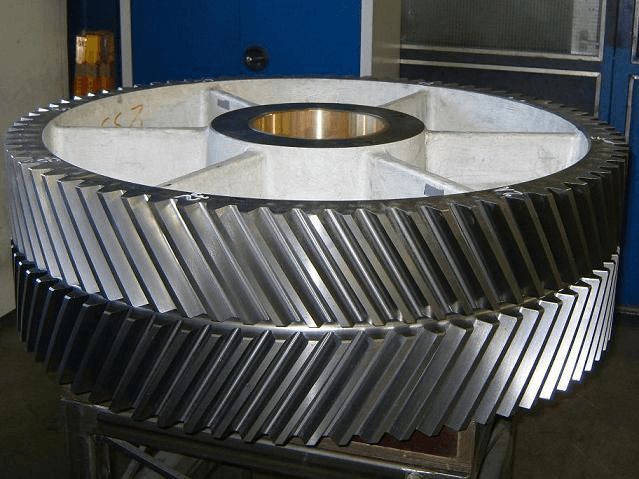

1. Tooth Design: Herringbone gears have a unique V-shaped or herringbone-shaped tooth profile. This design is formed by two helical gear sections that are mirror images of each other. In contrast, other gears, such as spur gears, helical gears, bevel gears, or worm gears, have different tooth profiles and configurations.

2. Axial Thrust Elimination: One of the key differentiating factors of herringbone gears is their ability to eliminate or greatly reduce axial thrust forces. In helical gears, the helix angle of the teeth generates an axial force during rotation, requiring the use of thrust bearings to counteract the thrust loads. Herringbone gears, with their double helix design, have opposing helix angles that cancel out the axial forces, eliminating the need for thrust bearings.

3. Noisy Cancellation: Herringbone gears are known for their noise-canceling properties. The opposing helix angles of the two gear sections help reduce vibrations and noise during operation. This is particularly beneficial in applications where noise reduction is critical, such as printing presses or precision machinery.

4. Increased Load Capacity: The V-shaped tooth profile of herringbone gears provides increased tooth contact area compared to other gears with straight or helical teeth. This increased contact area improves load distribution and allows herringbone gears to handle higher torque loads, resulting in an increased load-carrying capacity.

5. Bidirectional Power Transmission: Herringbone gears are designed to transmit power bidirectionally. The symmetrical tooth profiles of herringbone gears enable power transmission in both directions, making them suitable for applications where reversing or bidirectional power transfer is required.

6. Smooth Operation: Due to their double helix design, herringbone gears provide smooth and gradual tooth engagement. This gradual meshing reduces sliding friction, minimizes backlash, and ensures a continuous transfer of power. This characteristic makes herringbone gears desirable in applications where smooth operation and high efficiency are crucial.

7. Complex Manufacturing: Herringbone gears have a more complex manufacturing process compared to some other gear types. The creation of the herringbone tooth profile requires specific machining techniques and precision to ensure proper meshing and alignment of the gear sections.

It’s important to note that the selection of gear type depends on the specific requirements of the application. While herringbone gears offer unique advantages, other gear types may be more suitable in certain scenarios based on factors such as space limitations, cost, torque requirements, and operating conditions.

In summary, herringbone gears stand out with their distinctive tooth design, axial thrust elimination, noise-canceling properties, increased load capacity, bidirectional power transmission, smooth operation, and complex manufacturing process, making them well-suited for various industrial applications.

editor by Dream 2024-05-02

China Best Sales Transmit Significant Power Herringbone Gear with Best Sales

Product Description

Product Description

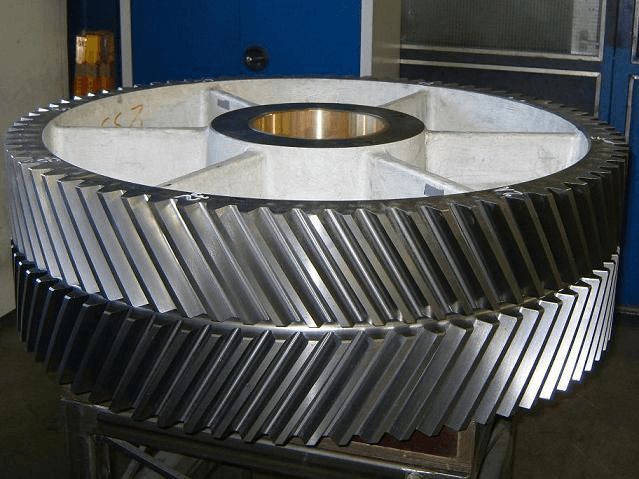

Herringbone gears are a specific type of gear that feature a unique double helix shape resembling the bones of a fish, hence the name “herringbone.” They are characterized by their distinctive V-shaped teeth that are arranged in a herringbone pattern.

Features

Double Helix Shape: The most distinctive characteristic of herringbone gears is their double helix shape, which allows for smoother and more efficient operation compared to traditional spur gears.

Self-Aligning: Due to the opposing helix angles on either side of the gear, herringbone gears are self-aligning. This helps to reduce axial thrust and prevents gear misalignment.

High Load Capacity: Herringbone gears are capable of handling high loads and transmitting significant amounts of power due to their robust design.

Reduced Vibration and Noise: The double helix design helps to cancel out axial forces and minimize vibration and noise during operation, making them ideal for applications where noise reduction is important.

Functions

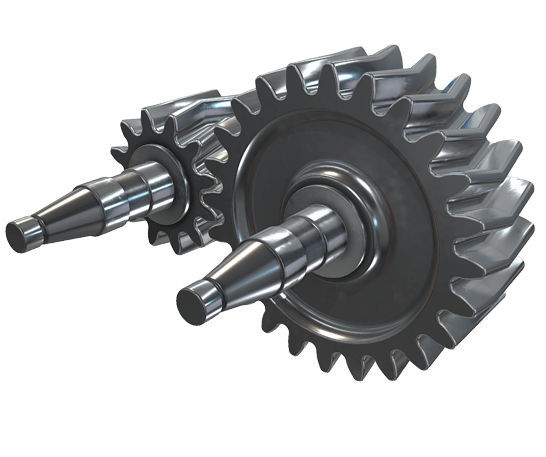

Power Transmission: Like other types of gears, herringbone gears are primarily used to transmit power between parallel shafts while maintaining a constant speed ratio.

Direction Change: Herringbone gears can change the direction of rotation between 2 shafts while transmitting power efficiently.

Speed Reduction or Increase: By using herringbone gears with different numbers of teeth on the mating gears, speed reduction or increase can be achieved.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Double Helical Gear |

| Material: | Alloy Steel |

| Transport Package: | Wooden Case |

| Customization: |

Available

| Customized Request |

|---|

How do you choose the right size herringbone gear for your application?

Choosing the right size herringbone gear for your application involves considering several factors and performing engineering calculations. Here’s a detailed explanation of the steps involved in selecting the appropriate size herringbone gear:

- Determine the Application Requirements: Start by understanding the specific requirements of your application. Consider factors such as the input and output speeds, torque loads, power requirements, duty cycle, and operating conditions. Determine the desired service life, efficiency, and reliability expectations for the gear system.

- Calculate the Gear Ratios: Determine the required gear ratios based on the speed and torque requirements of your application. Gear ratios define the relationship between the rotational speeds and torques of the input and output shafts. Select appropriate gear ratios that fulfill the desired performance objectives.

- Calculate the Load and Torque: Estimate the maximum load and torque that the herringbone gear will experience during operation. Consider both static and dynamic loads, shock loads, and any potential overload conditions. Calculate the required torque capacity of the gear system based on these load considerations.

- Consider the Size and Space Constraints: Evaluate the available space and size constraints in your application. Measure the available distance for gear installation, including the gear’s diameter, width, and axial length. Consider any restrictions on the gear’s physical dimensions and ensure that the selected gear size fits within the available space.

- Determine the Gear Module: The gear module is a parameter that defines the size and number of gear teeth. Calculate the gear module based on the desired gear ratios, torque capacity, and available space. The gear module is typically determined by considering a balance between gear tooth strength, contact ratio, and manufacturing feasibility.

- Perform Gear Design Calculations: Utilize standard gear design formulas and calculations to determine the required number of gear teeth, pitch diameter, helix angles, and other gear dimensions. Consider factors such as gear tooth strength, contact ratio, tooth profile optimization, and gear manufacturing standards. These calculations ensure that the selected gear size can handle the anticipated loads and provide reliable performance.

- Consult Manufacturers and Standards: Consult gear manufacturers, industry standards, and guidelines to ensure compliance with best practices and safety requirements. Manufacturers can provide technical expertise, recommend suitable gear sizes, and offer guidance on material selection, heat treatment processes, and gear quality standards.

- Consider Cost and Availability: Evaluate the cost implications and availability of the selected gear size. Consider factors such as material costs, manufacturing complexity, lead times, and the overall economic feasibility of the gear system. Balance the desired performance with cost considerations to arrive at an optimal gear size.

It’s important to note that selecting the right size herringbone gear requires expertise in gear design and engineering. If you lack the necessary knowledge, it is advisable to consult with experienced gear engineers or manufacturers who can assist in the selection process.

In summary, choosing the right size herringbone gear involves determining the application requirements, calculating gear ratios and torque loads, considering size constraints, determining the gear module, performing gear design calculations, consulting manufacturers and standards, and considering cost and availability. Following these steps ensures that the selected herringbone gear size meets the specific needs of your application and provides reliable and efficient operation.

Are herringbone gears suitable for high-torque applications?

Herringbone gears are well-suited for high-torque applications due to their design characteristics and advantages. Here’s a detailed explanation of why herringbone gears are suitable for high-torque applications:

- Large Surface Area of Contact: Herringbone gears have a larger surface area of contact between the gear teeth compared to conventional spur gears. This increased contact area allows herringbone gears to distribute the torque load more effectively. The larger contact area helps prevent tooth deflection and distributes the load across a greater number of teeth, resulting in improved torque transmission capabilities.

- Higher Torque Capacity: The design of herringbone gears enables them to handle higher torque loads. The opposing helix angles of the teeth in herringbone gears cancel out the axial thrust, which is generated during gear meshing. This cancellation of axial thrust allows herringbone gears to transmit higher torque without the need for additional thrust bearings or mechanisms. The increased torque capacity of herringbone gears makes them suitable for demanding applications that require high torque transfer.

- Reduced Gear Tooth Deflection: Herringbone gears exhibit reduced tooth deflection compared to spur gears. The double helical arrangement of the teeth in herringbone gears helps counteract the bending forces that can cause tooth deflection. This characteristic allows herringbone gears to maintain a more precise gear mesh, even under high torque loads. The reduced tooth deflection enhances the overall performance and reliability of herringbone gears in high-torque applications.

- Compact Gearbox Design: The high torque capacity of herringbone gears enables the design of more compact gearboxes. The ability to transmit higher torque loads in a smaller package can be advantageous in applications where space is limited. The compact design not only saves space but also reduces the overall weight of the system, making herringbone gears suitable for high-torque applications with size and weight constraints.

- Smooth Operation: Herringbone gears provide smooth and precise gear engagement, even under high-torque conditions. The opposing helix angles of the teeth facilitate gradual meshing and unmeshing, reducing impact and shock loads. The smooth operation minimizes vibrations and noise, which is particularly important in high-torque applications where excessive vibrations can lead to premature wear or component failure.

While herringbone gears offer several advantages for high-torque applications, it’s important to consider other factors such as lubrication, gear material, and system design. Proper lubrication and the use of high-strength materials can further enhance the performance and durability of herringbone gears in high-torque applications. Additionally, system design considerations, such as proper alignment, stiffness, and maintenance practices, should be taken into account to ensure optimal performance and longevity of herringbone gears in high-torque scenarios.

What is a herringbone gear and how does it work?

A herringbone gear, also known as a double helical gear, is a specialized type of gear with a unique tooth design. Here’s a detailed explanation of what a herringbone gear is and how it works:

A herringbone gear consists of two helical gear sections that are mirror images of each other and are joined together to form a V-shaped or herringbone-shaped tooth profile. Unlike conventional helical gears, which have a single helix angle and a continuous spiral tooth profile, herringbone gears have two opposing helix angles, resulting in a “V” shape when viewed from the end.

The primary advantage of the herringbone gear design is its ability to eliminate axial thrust or end thrust forces that are generated in helical gears. In a conventional helical gear, the helix angle of the teeth causes an axial force along the gear’s axis during rotation. This axial force can create significant thrust loads that need to be counteracted using thrust bearings or other mechanisms.

By using the double helix design of herringbone gears, the opposing helix angles cancel out the axial forces generated by each helical section. This cancellation of axial forces eliminates the need for thrust bearings and allows herringbone gears to transmit torque smoothly without axial movement or thrust loads.

When a herringbone gear is in operation, the angled teeth of the two helical sections engage with each other, similar to how helical gears mesh. The contact between the teeth occurs gradually, starting from one end of the gear and progressing towards the other end. The overlapping or interlocking tooth profiles ensure a continuous and smooth transfer of power.

The herringbone gear design offers several advantages:

- Axial Load Balancing: The opposing helix angles in herringbone gears balance out the axial forces, eliminating the need for thrust bearings and reducing wear on the gear teeth.

- Increased Load Capacity: The V-shaped tooth profile of herringbone gears provides increased tooth contact area compared to a single helix gear. This leads to improved load distribution and higher load-carrying capacity.

- Reduced Vibration and Noise: The double helix design of herringbone gears helps cancel out vibrations and reduce noise during operation. The opposing helix angles minimize tooth deflection and ensure smoother engagement between the gear teeth.

- Bidirectional Power Transmission: Herringbone gears can transmit power in both directions due to their symmetrical tooth profiles. This makes them suitable for applications where reversing or bidirectional power transmission is required.

- High Efficiency: The continuous and gradual engagement of the herringbone gear teeth results in improved efficiency by reducing sliding friction and minimizing backlash.

Herringbone gears are commonly used in various industrial applications, including power transmission systems, heavy machinery, oil and gas equipment, marine propulsion systems, and high-speed gearboxes. Their unique design and benefits make them well-suited for applications that require high torque transmission, smooth operation, and minimal axial thrust.

editor by Dream 2024-04-22

China Custom High Load Capacity Reduced Vibration and Noise Wind Turbines Herringbone Gear bevel gear set

Product Description

Product Description

Herringbone gears are a specific type of gear that feature a unique double helix shape resembling the bones of a fish, hence the name “herringbone.” They are characterized by their distinctive V-shaped teeth that are arranged in a herringbone pattern.

Features

Double Helix Shape: The most distinctive characteristic of herringbone gears is their double helix shape, which allows for smoother and more efficient operation compared to traditional spur gears.

Self-Aligning: Due to the opposing helix angles on either side of the gear, herringbone gears are self-aligning. This helps to reduce axial thrust and prevents gear misalignment.

High Load Capacity: Herringbone gears are capable of handling high loads and transmitting significant amounts of power due to their robust design.

Reduced Vibration and Noise: The double helix design helps to cancel out axial forces and minimize vibration and noise during operation, making them ideal for applications where noise reduction is important.

Functions

Power Transmission: Like other types of gears, herringbone gears are primarily used to transmit power between parallel shafts while maintaining a constant speed ratio.

Direction Change: Herringbone gears can change the direction of rotation between 2 shafts while transmitting power efficiently.

Speed Reduction or Increase: By using herringbone gears with different numbers of teeth on the mating gears, speed reduction or increase can be achieved.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Double Helical Gear |

| Material: | Alloy Steel |

| Transport Package: | Wooden Case |

| Customization: |

Available

| Customized Request |

|---|

What is the purpose of using herringbone gears in machinery?

Using herringbone gears in machinery serves various purposes and offers several advantages. Here’s a detailed explanation of the purposes and benefits of using herringbone gears:

- Smooth and Quiet Operation: Herringbone gears are known for their ability to provide smooth and quiet operation. The double helical tooth design cancels out axial and radial forces, minimizing gear vibrations and reducing noise levels during engagement. This makes herringbone gears suitable for applications where noise reduction and smooth operation are essential, such as precision machinery, automotive transmissions, and gearboxes in industrial equipment.

- High Load Capacity: Herringbone gears have a high load-carrying capacity due to their double helical tooth profile. The opposing helix angles of the gear teeth distribute the load evenly, allowing for efficient power transmission even under heavy loads. This makes herringbone gears suitable for applications that involve high torque requirements and heavy-duty machinery, such as mining equipment, construction machinery, and marine propulsion systems.

- Bidirectional Power Transmission: Herringbone gears can transmit power in both directions without the need for additional thrust bearings or special mechanisms. The double helical tooth profile cancels out axial thrust forces, eliminating the net axial thrust on the gear shaft. This bidirectional power transmission capability makes herringbone gears suitable for applications where reversible power transfer is required, such as marine propulsion systems, locomotives, and machine tools.

- High-Speed Applications: Herringbone gears are well-suited for high-speed applications due to their enhanced tooth strength and efficient torque transfer. The double helical tooth design provides increased tooth contact area and improved load distribution, allowing for reliable power transmission at high rotational speeds. This makes herringbone gears suitable for applications such as turbo machinery, power generation equipment, and high-speed gearboxes.

- Reduced Wear and Improved Durability: The double helical tooth profile of herringbone gears helps to minimize wear and improve gear durability. The opposing helix angles distribute the load evenly across the gear teeth, reducing localized stress concentrations and minimizing the risk of tooth failure. This ensures long service life and reliable operation, making herringbone gears suitable for applications where durability and longevity are critical, such as heavy machinery, industrial equipment, and wind turbine systems.

- Efficient Power Transmission: Herringbone gears offer efficient power transmission due to their large contact area and overlapping tooth engagement. The double helical tooth profile provides a larger contact ratio compared to spur gears, allowing for a greater number of teeth in contact at any given time. This efficient torque transfer minimizes power losses and improves overall gear system efficiency, making herringbone gears suitable for applications where energy efficiency is a priority, such as automotive transmissions, gearboxes, and power transmission systems.

The purpose of using herringbone gears in machinery is to achieve smooth and quiet operation, handle high loads, enable bidirectional power transmission, accommodate high-speed applications, ensure durability and longevity, and achieve efficient power transmission. These advantages make herringbone gears a preferred choice in various industries and applications where reliable and high-performance gearing solutions are required.

How do you maintain and service a herringbone gear system?

Maintaining and servicing a herringbone gear system is crucial for ensuring its optimal performance, longevity, and reliability. Regular maintenance and service activities help identify and address potential issues, minimize wear, and extend the lifespan of the gear system. Here’s a detailed explanation of how to maintain and service a herringbone gear system:

- Inspection: Conduct regular visual inspections of the gear system to identify any signs of wear, damage, or misalignment. Inspect the gear teeth, shafts, bearings, and other components for any visible abnormalities, such as pitting, scoring, cracks, or excessive wear. Check for oil leaks, loose fasteners, or any other potential issues that may affect the gear system’s performance.

- Lubrication: Ensure that the lubrication of the herringbone gear system is adequate and meets the manufacturer’s recommendations. Monitor the lubricant level and condition regularly. Check for proper lubricant distribution and coverage on the gear teeth and contact surfaces. Replenish or replace the lubricant as necessary to maintain the required film thickness and lubricating properties.

- Alignment and Clearance: Check and maintain proper shaft alignment to prevent misalignment-related issues. Use alignment tools such as dial indicators or laser alignment systems to verify the parallelism and concentricity of the gear system shafts. Ensure that the gear engagement is correct and that there is appropriate gear backlash. Make any necessary adjustments to optimize gear alignment and clearance as per the manufacturer’s guidelines.

- Fasteners and Connections: Regularly inspect and tighten all fasteners, such as bolts, set screws, or clamps, to ensure that they are securely fastened. Loose fasteners can lead to misalignment, vibration, and potential gear system failure. Follow the recommended torque specifications provided by the manufacturer when tightening the fasteners to avoid over-tightening or under-tightening.

- Monitoring and Analysis: Implement a monitoring and analysis program to track the performance of the herringbone gear system over time. This can include vibration analysis, temperature monitoring, and oil analysis. These techniques can help identify any abnormal conditions, such as excessive vibration, increased temperatures, or the presence of contaminants or wear particles in the lubricant. Regular analysis and monitoring can aid in detecting potential issues early and taking appropriate corrective actions.

- Repair and Replacement: If any signs of wear, damage, or abnormal conditions are detected during inspections or monitoring, take prompt action to address the issues. Depending on the severity of the problem, this may involve repairing or replacing worn or damaged components, such as gear teeth, bearings, or seals. Follow the manufacturer’s guidelines and consult with qualified technicians or professionals for any necessary repair or replacement procedures.

- Documentation and Record-keeping: Maintain accurate documentation and records of all maintenance and service activities performed on the herringbone gear system. This includes inspection reports, lubrication records, repair or replacement history, and any other relevant information. These records can serve as a reference for future maintenance, help track the gear system’s performance, and aid in troubleshooting or warranty claims if needed.

It is important to note that the specific maintenance and service requirements may vary depending on the gear system design, application, and operating conditions. Always refer to the manufacturer’s guidelines, technical documentation, and any applicable industry standards for the recommended maintenance practices and service intervals specific to your herringbone gear system.

What is a herringbone gear and how does it work?

A herringbone gear, also known as a double helical gear, is a specialized type of gear with a unique tooth design. Here’s a detailed explanation of what a herringbone gear is and how it works:

A herringbone gear consists of two helical gear sections that are mirror images of each other and are joined together to form a V-shaped or herringbone-shaped tooth profile. Unlike conventional helical gears, which have a single helix angle and a continuous spiral tooth profile, herringbone gears have two opposing helix angles, resulting in a “V” shape when viewed from the end.

The primary advantage of the herringbone gear design is its ability to eliminate axial thrust or end thrust forces that are generated in helical gears. In a conventional helical gear, the helix angle of the teeth causes an axial force along the gear’s axis during rotation. This axial force can create significant thrust loads that need to be counteracted using thrust bearings or other mechanisms.

By using the double helix design of herringbone gears, the opposing helix angles cancel out the axial forces generated by each helical section. This cancellation of axial forces eliminates the need for thrust bearings and allows herringbone gears to transmit torque smoothly without axial movement or thrust loads.

When a herringbone gear is in operation, the angled teeth of the two helical sections engage with each other, similar to how helical gears mesh. The contact between the teeth occurs gradually, starting from one end of the gear and progressing towards the other end. The overlapping or interlocking tooth profiles ensure a continuous and smooth transfer of power.

The herringbone gear design offers several advantages:

- Axial Load Balancing: The opposing helix angles in herringbone gears balance out the axial forces, eliminating the need for thrust bearings and reducing wear on the gear teeth.

- Increased Load Capacity: The V-shaped tooth profile of herringbone gears provides increased tooth contact area compared to a single helix gear. This leads to improved load distribution and higher load-carrying capacity.

- Reduced Vibration and Noise: The double helix design of herringbone gears helps cancel out vibrations and reduce noise during operation. The opposing helix angles minimize tooth deflection and ensure smoother engagement between the gear teeth.

- Bidirectional Power Transmission: Herringbone gears can transmit power in both directions due to their symmetrical tooth profiles. This makes them suitable for applications where reversing or bidirectional power transmission is required.

- High Efficiency: The continuous and gradual engagement of the herringbone gear teeth results in improved efficiency by reducing sliding friction and minimizing backlash.

Herringbone gears are commonly used in various industrial applications, including power transmission systems, heavy machinery, oil and gas equipment, marine propulsion systems, and high-speed gearboxes. Their unique design and benefits make them well-suited for applications that require high torque transmission, smooth operation, and minimal axial thrust.

editor by Dream 2024-04-19

China wholesaler Custom Herringbone Gear and Bevel Gear Jf700 Rear Axle 11: 37 worm and wheel gear

Product Description

1) According to the different strength and performance, we choose the steel with strong compression;

2) Using Germany professional software and our professional engineers to design products with more reasonable size and better performance; 3) We can customize our products according to the needs of our customers,Therefore, the optimal performance of the gear can be exerted under different working conditions;

4) Quality assurance in every step to ensure product quality is controllable.

Product Paramenters

| DRIVEN GEAR |

NUMBER OF TEETH |

11 |

|

MODULE |

11.89 | |

|

LENTH |

282 | |

|

OUTER DIAMETER |

ø154 |

|

|

DIRECTION OF SPIRAL |

L |

|

|

ACCURACY OF SPLINE |

3-M16-7H | |

|

NUMBER OF SPLINE |

26 |

|

DRIVEN GEAR |

NUMBER OF TEETH |

37 |

|

OUTER DIAMETER |

ø434 |

|

|

DIAMETER OF INNER HOLE |

ø250 |

|

|

ACCURACY OF SCREW |

16-M16*1.5-7H | |

|

CENTER DISTANCE OF SCREW HOLE |

ø280 |

|

|

DIRECTION OF SPIRALR |

R |

Company Profiles

Our company,HangZhou CHINAMFG Gear co.,Ltd , specialized in Hypoid and spiral bevel gear used in Automotive industry, was foundeded in 1996, with registered capital 136,8 square meter, with building area of 72,000 square meters. More than 500 employees work in our company.

We own more than 560 high-precise machining equipments, 10 Klingelnberg Oerlikon gear production lines, 36 Gleason gear production lines, 5 forging production lines 2 german Aichilin and 5 CHINAMFG CHINAMFG advanced automatic continuous heat treatment production lines. With the introducing the advanced Oerlikon C50 and P65 measuring center, we enhence our technology level and improve our product quality a lot. We offer better quality and good after-sale service with low price, which insure the good reputation. With the concept of “for the people, by technology, creativity, for the society, transfering friendship, honest”, we are trying to provice the world-top level product.

Our aim is: CHINAMFG Gear,world class, Drive the world.

According to the different strength and performance, we choose the steel with strong compression;Using Germany professional software and our professional engineers to design products with more reasonable size and better performance;We can customize our products according to the needs of our customers,Therefore, the optimal performance of the gear can be exerted under different working conditions;Quality assurance in every step to ensure product quality is controllable.

Our company had full quality management system and had been certified by ISO9001:2000, QS-9000:1998, ISO/TS16949 , which insure the entrance of international market.

Certification & honors

Packaging & Shipping

Packaging Detail:standard package(carton ,wooden pallet).

Shipping:Support Sea freight. Accept FOB,EXW,FAS,DES.

Cooperative customers

HangZhou CHINAMFG Gear Co., Ltd. adheres to the concept of “people-oriented, prosper with science and technology; create high-quality products, contribute to the society; turn friendship, and contribute sincerely”, and will strive to create world automotive axle spiral bevel gear products.

1.Do you provide samples?

Yes,we can offer free sample but not pay the cost of freight.

2.What about OEM?

Yes,we can do OEM according to your requirements.

3.How about after-sales service?

We have excellent after-sales service if you have any quanlity problem,you can contact us anytime.

4.What about package?

Stardard package or customized package as requirements.

5.How to ensure the quanlity of the products?

We can provide raw meterial report,metallographic examination and the accuracy testing etc.

6.How long is your delivery time?

Genarally it is 4-7 days.If customized it will be take 20 days according to your quantity. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Herringbone Gear |

| Material: | Cast Steel |

| Samples: |

US$ 175/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you install a herringbone gear system?

Installing a herringbone gear system requires careful attention to ensure proper alignment, engagement, and functionality. Here’s a detailed explanation of the steps involved in installing a herringbone gear system:

- Preparation: Before installation, gather all the necessary components, including the herringbone gears, shafts, bearings, and any associated hardware. Ensure that the gears and shafts are clean and free from any debris or contaminants that could affect their performance. Review the gear system’s specifications, including the gear ratios, torque requirements, and any specific installation guidelines provided by the manufacturer.

- Shaft Alignment: Proper shaft alignment is crucial for the smooth operation of a herringbone gear system. Align the shafts accurately to ensure that they are parallel and concentric with each other. This can be achieved using alignment tools such as dial indicators and laser alignment systems. Proper shaft alignment helps to minimize misalignment-related issues such as gear tooth wear, noise, and premature failure.

- Gear Engagement: Position the herringbone gears on their respective shafts, ensuring that they are correctly oriented and meshing properly. The double helical tooth profile of the herringbone gears requires careful engagement to prevent interference and ensure smooth operation. Pay attention to the gear backlash, which is the slight clearance between the gear teeth when they are not under load. Follow the manufacturer’s recommendations for the appropriate gear backlash and adjust as necessary.

- Bearing Installation: Install the appropriate bearings to support the gear shafts. Ensure that the bearings are aligned and properly seated in their housings. Use the specified lubrication method and apply the appropriate lubricant to the bearings to minimize friction and wear. Adequate lubrication is essential for the smooth operation and longevity of the gear system.

- Check Clearances: Once the gears, shafts, and bearings are installed, check for any interferences or clearances issues. Verify that there is sufficient clearance between the gear teeth, as well as between the gears and any adjacent components or structures. Ensure that there are no obstructions that could impede the rotational movement of the gears or cause damage during operation.

- Tightening and Fastening: Securely tighten all fasteners, such as bolts or set screws, to hold the gears, shafts, and bearings in place. Follow the recommended torque specifications provided by the manufacturer to ensure proper fastening without over-tightening, which could lead to excessive stress or deformation of the components.

- Testing and Adjustment: After installation, perform a thorough inspection and functional testing of the herringbone gear system. Rotate the shafts manually or using a suitable drive mechanism to check for smooth and proper gear engagement. Listen for any unusual noises, vibrations, or irregularities that could indicate misalignment or other issues. If necessary, make fine adjustments to the gear engagement, backlash, or shaft alignment to optimize the performance of the gear system.

It is important to note that the installation process may vary depending on the specific gear system design, size, and application requirements. Always refer to the manufacturer’s guidelines, technical documentation, and any applicable industry standards when installing a herringbone gear system to ensure proper installation and optimal performance.

What lubrication is required for herringbone gears?

Proper lubrication is essential for the smooth and efficient operation of herringbone gears. The lubricant used in herringbone gear systems plays a crucial role in reducing friction, minimizing wear, dissipating heat, and protecting the gear surfaces. Here’s a detailed explanation of the lubrication requirements for herringbone gears:

- Lubricant Selection: When selecting a lubricant for herringbone gears, it is important to consider factors such as load, speed, operating temperature, and environmental conditions. The lubricant should have suitable viscosity and additives to provide adequate film thickness and maintain lubrication under the anticipated operating conditions. Commonly used lubricants for herringbone gears include mineral oils, synthetic oils, and specialty lubricants formulated for gear applications.

- Viscosity: The viscosity of the lubricant is crucial for ensuring proper lubrication and film formation between the gear teeth. The lubricant should have sufficient viscosity to create an effective lubricating film that separates the gear surfaces and reduces friction. It should be able to maintain this film under the operating conditions, ensuring smooth gear engagement and minimizing wear. The appropriate viscosity grade is typically specified by the gear system manufacturer based on the gear design, load, and speed.

- Lubricant Application: The lubricant should be applied to the gear system in the appropriate manner to ensure uniform coverage and distribution. In most cases, herringbone gears are lubricated by immersion or splash lubrication, where the gears partially or fully submerge in the lubricant or have the lubricant splashed onto their surfaces. The lubricant should be directed towards the gear meshing area to ensure proper lubrication of the gear teeth and contact surfaces.

- Lubricant Maintenance: Regular lubricant maintenance is essential to ensure the continued performance and longevity of herringbone gears. This includes monitoring the lubricant condition, checking for contamination, and replenishing or replacing the lubricant as necessary. Over time, the lubricant may degrade, become contaminated with particles or moisture, or lose its effectiveness. Regular inspections and lubricant analysis can help identify any issues and determine the appropriate maintenance intervals for lubricant replacement or replenishment.

- Sealing and Contamination Prevention: Proper sealing of the gear housing or enclosure is important to prevent the ingress of contaminants, such as dust, dirt, or moisture, into the gear system. Contaminants can degrade the lubricant and lead to increased wear and damage to the gear surfaces. Seals, gaskets, or other appropriate sealing mechanisms should be employed to minimize the risk of contamination and maintain the integrity of the lubricant.

It is important to consult the gear system manufacturer’s recommendations and specifications regarding lubrication requirements. The manufacturer may provide specific guidelines regarding lubricant type, viscosity, application methods, and maintenance procedures based on the gear design and intended operating conditions. Adhering to these guidelines will help ensure optimal lubrication and maximize the performance and service life of herringbone gears.

How do herringbone gears differ from other types of gears?

Herringbone gears, also known as double helical gears, possess distinct characteristics that set them apart from other types of gears. Here’s a detailed explanation of how herringbone gears differ from other gears:

1. Tooth Design: Herringbone gears have a unique V-shaped or herringbone-shaped tooth profile. This design is formed by two helical gear sections that are mirror images of each other. In contrast, other gears, such as spur gears, helical gears, bevel gears, or worm gears, have different tooth profiles and configurations.

2. Axial Thrust Elimination: One of the key differentiating factors of herringbone gears is their ability to eliminate or greatly reduce axial thrust forces. In helical gears, the helix angle of the teeth generates an axial force during rotation, requiring the use of thrust bearings to counteract the thrust loads. Herringbone gears, with their double helix design, have opposing helix angles that cancel out the axial forces, eliminating the need for thrust bearings.

3. Noisy Cancellation: Herringbone gears are known for their noise-canceling properties. The opposing helix angles of the two gear sections help reduce vibrations and noise during operation. This is particularly beneficial in applications where noise reduction is critical, such as printing presses or precision machinery.

4. Increased Load Capacity: The V-shaped tooth profile of herringbone gears provides increased tooth contact area compared to other gears with straight or helical teeth. This increased contact area improves load distribution and allows herringbone gears to handle higher torque loads, resulting in an increased load-carrying capacity.

5. Bidirectional Power Transmission: Herringbone gears are designed to transmit power bidirectionally. The symmetrical tooth profiles of herringbone gears enable power transmission in both directions, making them suitable for applications where reversing or bidirectional power transfer is required.

6. Smooth Operation: Due to their double helix design, herringbone gears provide smooth and gradual tooth engagement. This gradual meshing reduces sliding friction, minimizes backlash, and ensures a continuous transfer of power. This characteristic makes herringbone gears desirable in applications where smooth operation and high efficiency are crucial.

7. Complex Manufacturing: Herringbone gears have a more complex manufacturing process compared to some other gear types. The creation of the herringbone tooth profile requires specific machining techniques and precision to ensure proper meshing and alignment of the gear sections.

It’s important to note that the selection of gear type depends on the specific requirements of the application. While herringbone gears offer unique advantages, other gear types may be more suitable in certain scenarios based on factors such as space limitations, cost, torque requirements, and operating conditions.

In summary, herringbone gears stand out with their distinctive tooth design, axial thrust elimination, noise-canceling properties, increased load capacity, bidirectional power transmission, smooth operation, and complex manufacturing process, making them well-suited for various industrial applications.

editor by CX 2024-04-17

China high quality Herringbone Gears and Helical Gears for Truck Transmission Parts gear box

Product Description

1) According to the different strength and performance, we choose the steel with strong compression;

2) Using Germany professional software and our professional engineers to design products with more reasonable size and better performance; 3) We can customize our products according to the needs of our customers,Therefore, the optimal performance of the gear can be exerted under different working conditions;

4) Quality assurance in every step to ensure product quality is controllable.

Product Paramenters

| DRIVEN GEAR |

NUMBER OF TEETH |

13 |

|

MODULE |

11.8919 | |

|

LENTH |

292.5 | |

|

OUTER DIAMETER |

ø184 |

|

|

DIRECTION OF SPIRAL |

L |

|

|

ACCURACY OF SPLINE |

M45*1.5-6H | |

|

NUMBER OF SPLINE |

28 |

|

DRIVEN GEAR |

NUMBER OF TEETH |

37 |

|

OUTER DIAMETER |

ø435 |

|

|

DIAMETER OF INNER HOLE |

ø280 |

|

|

ACCURACY OF SCREW |

16-M16*1.5-4H5H | |

|

CENTER DISTANCE OF SCREW HOLE |

ø316 |

|

|

DIRECTION OF SPIRAL |

R |

Company Profiles

Our company,HangZhou CHINAMFG Gear co.,Ltd , specialized in Hypoid and spiral bevel gear used in Automotive industry, was foundeded in 1996, with registered capital 136,8 square meter, with building area of 72,000 square meters. More than 500 employees work in our company.

We own more than 560 high-precise machining equipments, 10 Klingelnberg Oerlikon gear production lines, 36 Gleason gear production lines, 5 forging production lines 2 german Aichilin and 5 CHINAMFG CHINAMFG advanced automatic continuous heat treatment production lines. With the introducing the advanced Oerlikon C50 and P65 measuring center, we enhence our technology level and improve our product quality a lot. We offer better quality and good after-sale service with low price, which insure the good reputation. With the concept of “for the people, by technology, creativity, for the society, transfering friendship, honest”, we are trying to provice the world-top level product.

Our aim is: CHINAMFG Gear,world class, Drive the world.

According to the different strength and performance, we choose the steel with strong compression;Using Germany professional software and our professional engineers to design products with more reasonable size and better performance;We can customize our products according to the needs of our customers,Therefore, the optimal performance of the gear can be exerted under different working conditions;Quality assurance in every step to ensure product quality is controllable.

Our company had full quality management system and had been certified by ISO9001:2000, QS-9000:1998, ISO/TS16949 , which insure the entrance of international market.

Certification & honors

Packaging & Shipping

Packaging Detail:standard package(carton ,wooden pallet).

Shipping:Support Sea freight. Accept FOB,EXW,FAS,DES.

Cooperative customers

HangZhou CHINAMFG Gear Co., Ltd. adheres to the concept of “people-oriented, prosper with science and technology; create high-quality products, contribute to the society; turn friendship, and contribute sincerely”, and will strive to create world automotive axle spiral bevel gear products.

1.Do you provide samples?

Yes,we can offer free sample but not pay the cost of freight.

2.What about OEM?

Yes,we can do OEM according to your requirements.

3.How about after-sales service?

We have excellent after-sales service if you have any quanlity problem,you can contact us anytime.

4.What about package?

Stardard package or customized package as requirements.

5.How to ensure the quanlity of the products?

We can provide raw meterial report,metallographic examination and the accuracy testing etc.

6.How long is your delivery time?

Genarally it is 4-7 days.If customized it will be take 20 days according to your quantity. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Herringbone Gear |

| Material: | Cast Steel |

| Samples: |

US$ 154/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is the purpose of using herringbone gears in machinery?

Using herringbone gears in machinery serves various purposes and offers several advantages. Here’s a detailed explanation of the purposes and benefits of using herringbone gears:

- Smooth and Quiet Operation: Herringbone gears are known for their ability to provide smooth and quiet operation. The double helical tooth design cancels out axial and radial forces, minimizing gear vibrations and reducing noise levels during engagement. This makes herringbone gears suitable for applications where noise reduction and smooth operation are essential, such as precision machinery, automotive transmissions, and gearboxes in industrial equipment.

- High Load Capacity: Herringbone gears have a high load-carrying capacity due to their double helical tooth profile. The opposing helix angles of the gear teeth distribute the load evenly, allowing for efficient power transmission even under heavy loads. This makes herringbone gears suitable for applications that involve high torque requirements and heavy-duty machinery, such as mining equipment, construction machinery, and marine propulsion systems.

- Bidirectional Power Transmission: Herringbone gears can transmit power in both directions without the need for additional thrust bearings or special mechanisms. The double helical tooth profile cancels out axial thrust forces, eliminating the net axial thrust on the gear shaft. This bidirectional power transmission capability makes herringbone gears suitable for applications where reversible power transfer is required, such as marine propulsion systems, locomotives, and machine tools.

- High-Speed Applications: Herringbone gears are well-suited for high-speed applications due to their enhanced tooth strength and efficient torque transfer. The double helical tooth design provides increased tooth contact area and improved load distribution, allowing for reliable power transmission at high rotational speeds. This makes herringbone gears suitable for applications such as turbo machinery, power generation equipment, and high-speed gearboxes.

- Reduced Wear and Improved Durability: The double helical tooth profile of herringbone gears helps to minimize wear and improve gear durability. The opposing helix angles distribute the load evenly across the gear teeth, reducing localized stress concentrations and minimizing the risk of tooth failure. This ensures long service life and reliable operation, making herringbone gears suitable for applications where durability and longevity are critical, such as heavy machinery, industrial equipment, and wind turbine systems.

- Efficient Power Transmission: Herringbone gears offer efficient power transmission due to their large contact area and overlapping tooth engagement. The double helical tooth profile provides a larger contact ratio compared to spur gears, allowing for a greater number of teeth in contact at any given time. This efficient torque transfer minimizes power losses and improves overall gear system efficiency, making herringbone gears suitable for applications where energy efficiency is a priority, such as automotive transmissions, gearboxes, and power transmission systems.

The purpose of using herringbone gears in machinery is to achieve smooth and quiet operation, handle high loads, enable bidirectional power transmission, accommodate high-speed applications, ensure durability and longevity, and achieve efficient power transmission. These advantages make herringbone gears a preferred choice in various industries and applications where reliable and high-performance gearing solutions are required.

Are herringbone gears suitable for high-torque applications?

Herringbone gears are well-suited for high-torque applications due to their design characteristics and advantages. Here’s a detailed explanation of why herringbone gears are suitable for high-torque applications:

- Large Surface Area of Contact: Herringbone gears have a larger surface area of contact between the gear teeth compared to conventional spur gears. This increased contact area allows herringbone gears to distribute the torque load more effectively. The larger contact area helps prevent tooth deflection and distributes the load across a greater number of teeth, resulting in improved torque transmission capabilities.

- Higher Torque Capacity: The design of herringbone gears enables them to handle higher torque loads. The opposing helix angles of the teeth in herringbone gears cancel out the axial thrust, which is generated during gear meshing. This cancellation of axial thrust allows herringbone gears to transmit higher torque without the need for additional thrust bearings or mechanisms. The increased torque capacity of herringbone gears makes them suitable for demanding applications that require high torque transfer.

- Reduced Gear Tooth Deflection: Herringbone gears exhibit reduced tooth deflection compared to spur gears. The double helical arrangement of the teeth in herringbone gears helps counteract the bending forces that can cause tooth deflection. This characteristic allows herringbone gears to maintain a more precise gear mesh, even under high torque loads. The reduced tooth deflection enhances the overall performance and reliability of herringbone gears in high-torque applications.

- Compact Gearbox Design: The high torque capacity of herringbone gears enables the design of more compact gearboxes. The ability to transmit higher torque loads in a smaller package can be advantageous in applications where space is limited. The compact design not only saves space but also reduces the overall weight of the system, making herringbone gears suitable for high-torque applications with size and weight constraints.

- Smooth Operation: Herringbone gears provide smooth and precise gear engagement, even under high-torque conditions. The opposing helix angles of the teeth facilitate gradual meshing and unmeshing, reducing impact and shock loads. The smooth operation minimizes vibrations and noise, which is particularly important in high-torque applications where excessive vibrations can lead to premature wear or component failure.

While herringbone gears offer several advantages for high-torque applications, it’s important to consider other factors such as lubrication, gear material, and system design. Proper lubrication and the use of high-strength materials can further enhance the performance and durability of herringbone gears in high-torque applications. Additionally, system design considerations, such as proper alignment, stiffness, and maintenance practices, should be taken into account to ensure optimal performance and longevity of herringbone gears in high-torque scenarios.

Can you explain the unique shape of herringbone gear teeth?

The unique shape of herringbone gear teeth is a defining characteristic of herringbone gears, also known as double helical gears. Here’s a detailed explanation of the unique shape of herringbone gear teeth:

Herringbone gears have a V-shaped or herringbone-shaped tooth profile, which is formed by two helical gear sections that are mirror images of each other. This tooth profile is distinct from the straight or helical tooth profiles found in other types of gears such as spur gears or helical gears.

When viewed from the end, the teeth of a herringbone gear resemble the letter “V”. This shape is created by the combination of two opposing helix angles, one on each side of the gear. The helix angle refers to the angle at which the teeth are inclined relative to the gear’s axis.

In a herringbone gear, the helix angle of one helical section is opposite in direction to the helix angle of the other helical section. This means that as the gear rotates, the teeth on one side lean in one direction, while the teeth on the other side lean in the opposite direction.

The opposing helix angles of the two gear sections in herringbone gears serve several important purposes:

- Axial Thrust Elimination: One of the main advantages of the herringbone gear design is the elimination of axial thrust or end thrust forces. In helical gears, the helix angle of the teeth generates an axial force along the gear’s axis during rotation. However, in herringbone gears, the opposing helix angles cancel out these axial forces, resulting in a balanced gear that does not experience significant axial movement or require thrust bearings.

- Smooth Engagement: The opposing helix angles of herringbone gears facilitate smooth and gradual tooth engagement. As the gear rotates, the teeth on one side gradually come into contact with the teeth on the other side. This gradual meshing reduces sliding friction, minimizes backlash, and ensures a continuous and smooth transfer of power between the gear sections.

- Increased Load Capacity: The V-shaped tooth profile of herringbone gears provides increased tooth contact area compared to gears with straight or helical teeth. This increased contact area improves load distribution and allows herringbone gears to handle higher torque loads, resulting in an increased load-carrying capacity.

The unique shape of herringbone gear teeth requires precise manufacturing techniques to ensure proper meshing and alignment of the gear sections. The teeth must be accurately machined to achieve the correct helix angles and tooth profiles, ensuring smooth operation and efficient power transmission.

In summary, the unique shape of herringbone gear teeth, with their V-shaped or herringbone-shaped profile formed by opposing helix angles, enables axial thrust elimination, smooth engagement, and increased load capacity. These characteristics make herringbone gears well-suited for applications where efficient torque transmission, balanced operation, and high load-carrying capacity are essential.

editor by CX 2024-04-15

China Best Sales Heavy Vehicles Double Helical and Herringbone Gears spiral bevel gear

Product Description

Product Description

A double helical gear is a type of gear that consists of 2 parallel helical gears with opposite helix angles, which are connected by a central web. The helix angle refers to the angle between the gear’s teeth and its axis of rotation.

Double helical gears are also known as herringbone gears, due to their resemblance to the bones of a herring fish. They are designed to provide smooth and quiet operation, as the opposing helices of the gears cancel out the axial forces and minimize the axial thrust that is created by a single helix gear.

Machinery processing

Applications

Industrial Machinery: Double helical gears are often used in heavy-duty industrial machinery such as turbines, compressors, and generators, where high loads and torque transmission are required.

Automotive Industry: Double helical gears are used in automotive transmissions, where they provide smooth and quiet operation and high torque transmission.

Marine Industry: Double helical gears are used in marine propulsion systems, where they provide high load capacity and efficiency.

Robotics: Double helical gears are used in precision robotics, where accuracy and smooth operation are critical.

Machine Tools: Double helical gears are used in precision machine tools such as milling machines, where high accuracy and stability are required.

Aerospace Industry: Double helical gears are used in aerospace applications such as helicopter transmissions, where high load capacity and smooth operation are critical.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Double Helical Gear |

| Material: | 42CrMo |

| Transport Package: | Wooden Case |

| Customization: |

Available

| Customized Request |

|---|

How do you choose the right size herringbone gear for your application?

Choosing the right size herringbone gear for your application involves considering several factors and performing engineering calculations. Here’s a detailed explanation of the steps involved in selecting the appropriate size herringbone gear:

- Determine the Application Requirements: Start by understanding the specific requirements of your application. Consider factors such as the input and output speeds, torque loads, power requirements, duty cycle, and operating conditions. Determine the desired service life, efficiency, and reliability expectations for the gear system.

- Calculate the Gear Ratios: Determine the required gear ratios based on the speed and torque requirements of your application. Gear ratios define the relationship between the rotational speeds and torques of the input and output shafts. Select appropriate gear ratios that fulfill the desired performance objectives.

- Calculate the Load and Torque: Estimate the maximum load and torque that the herringbone gear will experience during operation. Consider both static and dynamic loads, shock loads, and any potential overload conditions. Calculate the required torque capacity of the gear system based on these load considerations.

- Consider the Size and Space Constraints: Evaluate the available space and size constraints in your application. Measure the available distance for gear installation, including the gear’s diameter, width, and axial length. Consider any restrictions on the gear’s physical dimensions and ensure that the selected gear size fits within the available space.

- Determine the Gear Module: The gear module is a parameter that defines the size and number of gear teeth. Calculate the gear module based on the desired gear ratios, torque capacity, and available space. The gear module is typically determined by considering a balance between gear tooth strength, contact ratio, and manufacturing feasibility.

- Perform Gear Design Calculations: Utilize standard gear design formulas and calculations to determine the required number of gear teeth, pitch diameter, helix angles, and other gear dimensions. Consider factors such as gear tooth strength, contact ratio, tooth profile optimization, and gear manufacturing standards. These calculations ensure that the selected gear size can handle the anticipated loads and provide reliable performance.

- Consult Manufacturers and Standards: Consult gear manufacturers, industry standards, and guidelines to ensure compliance with best practices and safety requirements. Manufacturers can provide technical expertise, recommend suitable gear sizes, and offer guidance on material selection, heat treatment processes, and gear quality standards.

- Consider Cost and Availability: Evaluate the cost implications and availability of the selected gear size. Consider factors such as material costs, manufacturing complexity, lead times, and the overall economic feasibility of the gear system. Balance the desired performance with cost considerations to arrive at an optimal gear size.

It’s important to note that selecting the right size herringbone gear requires expertise in gear design and engineering. If you lack the necessary knowledge, it is advisable to consult with experienced gear engineers or manufacturers who can assist in the selection process.

In summary, choosing the right size herringbone gear involves determining the application requirements, calculating gear ratios and torque loads, considering size constraints, determining the gear module, performing gear design calculations, consulting manufacturers and standards, and considering cost and availability. Following these steps ensures that the selected herringbone gear size meets the specific needs of your application and provides reliable and efficient operation.

Can you provide examples of machinery that use herringbone gears?

Herringbone gears are widely used in various machinery and mechanical systems that require high torque transmission, smooth operation, and reduced noise levels. Here are some examples of machinery and applications where herringbone gears are commonly employed:

- Marine Propulsion Systems: Herringbone gears are commonly found in marine propulsion systems, including ship engines and marine gearboxes. They are used to transmit power from the engine to the propeller shaft, providing efficient torque transfer and smooth operation in marine vessels.

- Mining Equipment: Herringbone gears are used in heavy-duty mining equipment, such as crushers, conveyors, and excavators. These gears can handle high loads and provide reliable power transmission in demanding mining operations.

- Turbines and Power Generation: Herringbone gears are utilized in various power generation applications, including steam turbines and hydroelectric generators. They help transmit torque from the turbine or generator shaft to other components, such as the gearbox or electrical generator, ensuring efficient power generation.

- Rotating Kilns and Dryers: Herringbone gears are commonly employed in rotating kilns and dryers used in industries such as cement manufacturing and chemical processing. These gears facilitate the rotation of the kiln or dryer, ensuring proper heat distribution and material processing.

- Metal Rolling Mills: Herringbone gears are utilized in metal rolling mills to transmit power from the motor to the rollers. They enable precise and synchronized movement of the rolls, allowing for the shaping and forming of metal sheets or bars in the rolling process.

- Paper and Pulp Industry: Herringbone gears are used in machinery and equipment involved in the paper and pulp industry, such as paper machines, pulpers, and digesters. These gears facilitate the movement of various components, including rollers and conveyors, ensuring smooth and efficient paper production processes.

- Textile Machinery: Herringbone gears find applications in textile machinery, including spinning machines, weaving looms, and knitting machines. They assist in the movement and synchronization of various components, such as spindles, shuttles, and fabric feeders, enabling precise and efficient textile production.

- Machine Tools: Herringbone gears are utilized in machine tools, such as gear hobbing machines, milling machines, and lathes. These gears help transmit power from the motor to the tooling components, allowing for precise and controlled machining operations.

These examples represent just a few of the many applications where herringbone gears are employed. Herringbone gears are valued for their ability to handle high loads, provide smooth operation, and reduce noise levels, making them suitable for a wide range of machinery and mechanical systems.

Are there different variations of herringbone gears available?

Yes, there are different variations of herringbone gears available to suit specific application requirements. Here’s a detailed explanation of some of the common variations of herringbone gears:

- Single- and Double-Sided: Herringbone gears can be classified as single-sided or double-sided based on the number of helical sections. Single-sided herringbone gears have a herringbone tooth profile on one side and a straight tooth profile on the other side. Double-sided herringbone gears have herringbone tooth profiles on both sides. Single-sided herringbone gears are commonly used when axial thrust elimination is not a primary requirement, while double-sided herringbone gears provide superior axial thrust cancellation.

- Conventional and Low-Backlash: Herringbone gears can also be categorized as conventional or low-backlash based on their tooth design and manufacturing precision. Conventional herringbone gears have standard tooth profiles and may exhibit some level of backlash, which is the slight clearance between the mating teeth. Low-backlash herringbone gears are designed and manufactured with tighter tolerances to minimize or eliminate backlash, resulting in improved precision and reduced vibration.

- Materials and Coatings: Herringbone gears can be made from various materials depending on the application requirements. Common materials include steel, cast iron, bronze, and non-ferrous alloys. Additionally, surface coatings such as nitriding or carburizing can be applied to enhance the gear’s hardness, wear resistance, and durability. The choice of material and coating depends on factors like load capacity, operating conditions, and cost considerations.

- Customized Geometries: Herringbone gears can be customized to specific geometries and specifications based on the application requirements. This includes variations in tooth dimensions, helix angles, pressure angles, and gear module (the ratio of the gear’s pitch diameter to the number of teeth). Customized geometries allow herringbone gears to be optimized for specific torque loads, speed ranges, and space constraints.

- Integrated Components: In some applications, herringbone gears may be integrated with other components to form specialized gear systems. For example, herringbone gears can be combined with planetary gear systems to create herringbone planetary gears, which offer high torque capacity and compact design. These integrated variations provide specific advantages in terms of load distribution, torque transmission, and overall system efficiency.